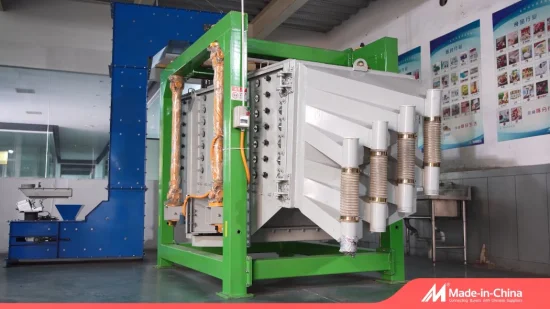

High Precision Calcite Powder Gyratory Vibrating Screen Automatic Square Swing Shaker Sieve

Description

Basic Info.

| Model NO. | HXS-2040 |

| Material | Carbon Steel |

| Material Feature | as Per Model |

| Certification | ISO9001:2008, ISO9001:2000, CE |

| Energy Saving | Energy Saving |

| Warranty | 1 Year |

| Color | Multi Color |

| Customized | Customized |

| Condition | New |

| After-sales Service | Support |

| Cleaning System | Bouncing Ball |

| Application | Powder/Granule |

| Video Outgoing-Inspection | Provided |

| Machinery Test Report | Provided |

| Capacity | by Model |

| Function | Screening\Separation\Sorting\Sieving |

| Layer(S) | 1-9 Layers |

| Mesh Size | 2~500 Mesh |

| Advantage | High Precision and Large Output |

| Product Name | Gyratory Square Vibrating Sieve |

| Transport Package | Wooden Box |

| Specification | Vibrating Screen |

| Trademark | Gaofu |

| Origin | Henan, China |

| Production Capacity | 10000set/Year |

Packaging & Delivery

Package Size 260.00cm * 200.00cm * 230.00cm Package Gross Weight 4500.000kgProduct Description

Product Description

Square Shaker

Square swinging screen, also known as rectangular swinging screen, is a high-efficiency screening equipment with high precision and large output. It has better self-cleaning effect, high screen utilization rate, long life and good sealing effect.

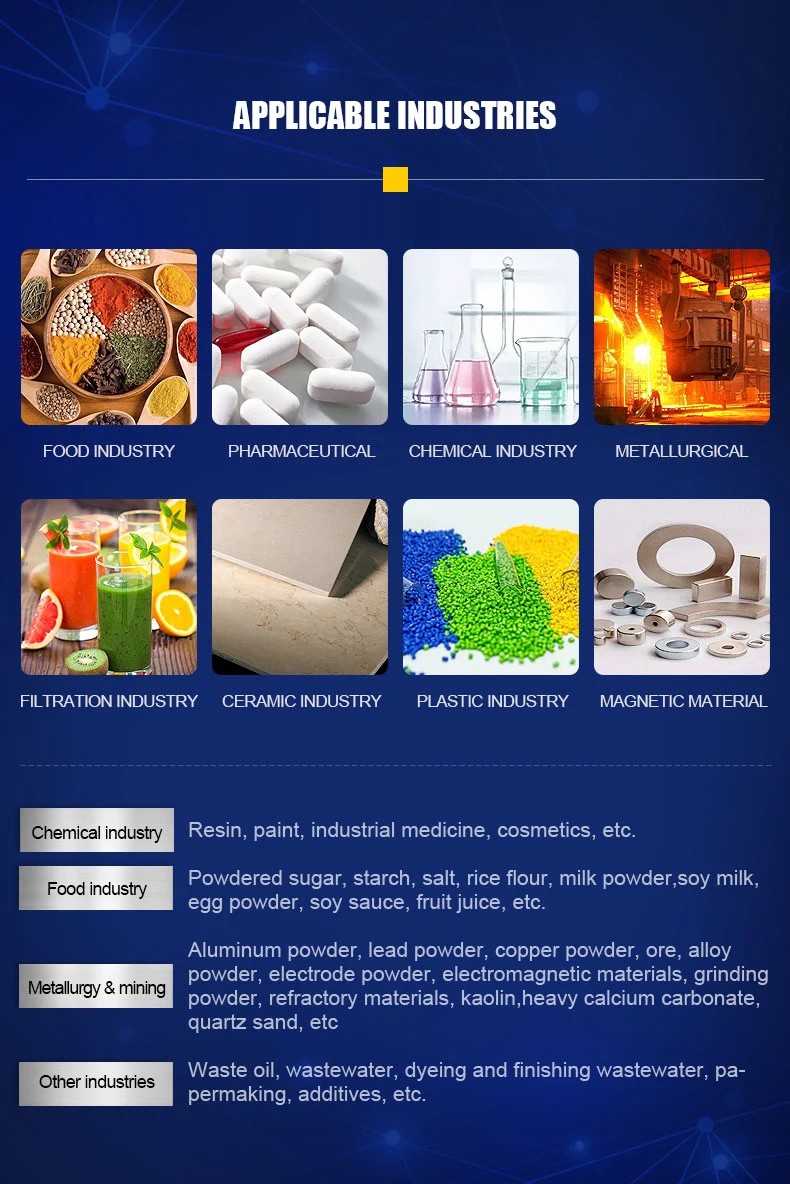

The square swinging screen is widely used in chemical industry and new materials, metallurgy, metal powder, mineral powder, food, salt, sugar, abrasive, feed and other industries. Through the square swinging vibrating screen, the whirling motion of the exciter is transmitted to the screen surface, so that the materials are quickly dispersed in the front of the screen machine, so as to achieve the purpose of high-efficiency screening.

The square swinging screen adopts many new processes and standardized design schemes, which can be combined with production conditions and different customer needs to achieve a variety of combination modes. At the same time, the design concept also considers the convenience and safety of transportation, and the overall dimensions of the equipment are designed in combination with the transportation vehicles. Both the dust cover and the force transmission plate of the exciter are stamped and formed by a large press at one time, which increases the strength and reduces the weight of the equipment. The plate is made of cold-rolled plate, which is more unique in mechanical design and achieves the design concept of high efficiency and energy saving.

Scope of application

Building materials, mineral processing, metallurgy, chemical industry, abrasives, food and other industries

Applicable materials

Dry powder mortar, machine-made sand, natural sand, quartz sand, perlite, dolomite, calcite, potassium feldspar and other stone powder and mineral powder; metallurgy, metal powder, mineral powder, food, sugar, salt, abrasive, Grading of feed and other industries.

Product Features

Large screening capacity, unique multi-layer grading design, one machine is divided into two groups, one machine can be used for multiple machines, and the output is doubled.

Fully enclosed structure, no dust flying, small vibration and low noise of the sieve machine, which meets the requirements of environmental protection.

Flexible screening, the acceleration is 4-5 times lower than ordinary vibrating screens, and the service life is improved, thereby reducing maintenance costs.

It is more convenient to change the screen, simple to operate, firm and reliable.

Large-scale electrostatic spraying process, the equipment is more beautiful, wear-resistant and anti-rust.

Rotary screening: Two layers of screens with the same aperture allow the materials that have been screened once to be screened again to achieve higher screening accuracy.

Rotary reverse sieving: material sieving is sieved from fine→medium fine→medium→coarse, and the coarse material plays a certain role in cleaning the mesh.

Product Parameters

Working Principle

After the screen machine is started, the shaking body of the screen machine, that is, the screen box, reciprocates back and forth under the action of inertial force, and the screen box drives the screen surface to shake periodically, so that the materials on the screen surface make directional jumping motion together with the screen box, During this period, the material smaller than the aperture of the screen surface falls to the lower layer through the sieve hole and becomes the undersieve, and the material larger than the aperture of the screen surface is discharged from the discharge port after continuous tumbling and jumping motion, thus completing the screening work.

| Model | Screen size (m) | Screening area(m²) | Screen inclination (°) | Number of screenlayers (s) | Power(kW) | Allowable number of rotations | Screen boxstroke (mm) |

| HXS-1536 | 1.5m*3.5m | 5.25 | 5.43±3 | 1~10 | 5.5 | 180-260 | 60-25 |

| HXS-1836 | 1.8m*3.5m | 6.3 | 5.43±3 | 5.5 | 180-260 | 60-25 | |

| HXS-2040 | 2.0m*4.0m | 8 | 5.43±3 | 7.5 | 180-260 | 60-25 |

Packaging & Shipping

Recommended Featured

Certifications

Company Profile

FAQ

1. who are we?

We are based in Henan, China, start from 2000,sell to Southeast Asia(40.00%),Domestic Market(27.00%),South America(10.00%),Eastern Europe(8.00%),Oceania(3.00%),North America(2.00%),Western Europe(2.00%),Africa(2.00%),South Asia(1.00%),Eastern Asia(1.00%),Southern Europe(1.00%),Central America(1.00%),Northern Europe(1.00%),Mid East(1.00%). There are total about 301-500 people in our office.2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Vibrating Screen Equipment, Crusher, Conveying Equipment, Mixer, Food Feeding And Screening System

4. why should you buy from us not from other suppliers?

Gaofu company founded in 1982, 20 years screening experience, the company covers an area of 50800 square meters.we posses the independent management right of importing and exporting, our products are spread all over the country, sold in faraway market area

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Contact Us

Tell me the following questions, Then I can send you accurate quotation soon, including additional discount!Your email addressand telephone will not be shared or published!The proper selection of the vibrating screen depends on the material, mesh size,output required, method of input,abrasiveness of the material etc: 1. Screening product : _____2. Moisture:_____%3. Capacity:________kg/ hour4. Screen layer:_______5. Screen mesh size:______ mesh . ______ mesh. ______ mesh6. Voltage:______V,Frequency:______HZ, 3 phase7. SS304/316L stainless steel or Q235A carbon steel?

Prev: Horizontal Leaf Filter for Oil and Chemical Industry

Next: New Horizontal Pressure Leaf Filter for Edible Oil and Beverage Industry

Our Contact