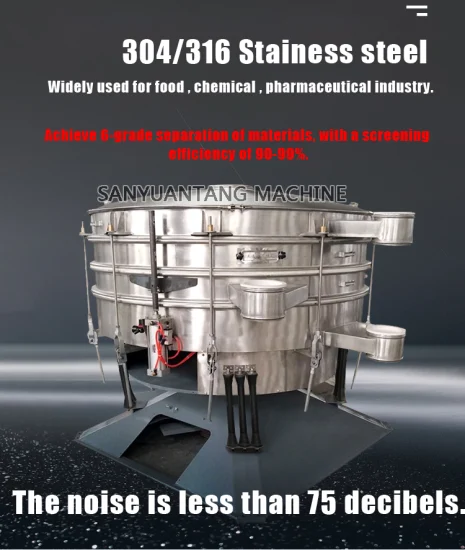

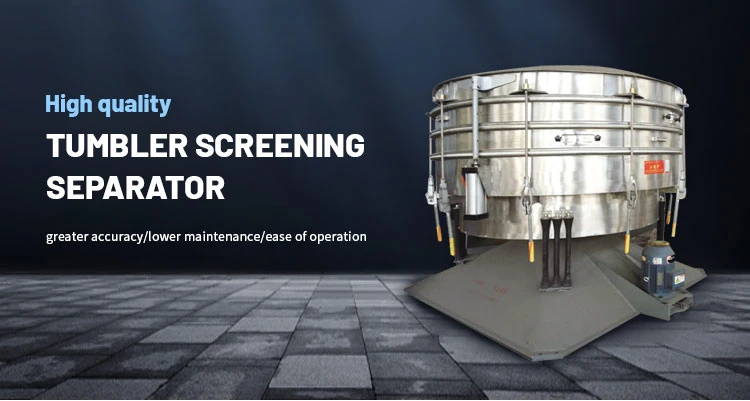

Electric Sieve Stainless Steel Screen Machine Powder Flour Sifter Vibration Screen Circular Tumbler Screen Machine

Description

Basic Info.

| Model NO. | YBS-1200-2S |

| Shaft Number | Double |

| Running Track | Circular Vibrating Screen |

| Supporting Device | Coil Spring |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| After-sales Service | None |

| Diameter | 1000mm-2600mm |

| Capacity | 10kg-2000kg |

| Used for | Powder Screening |

| Feature | Screening Materials |

| Screen Mesh | 1-635 Mesh |

| Motor | Vertical Vibrating Motor |

| Layer(S) | 1-5 Layers |

| Keyword | Vibration Sieve |

| Product Name | Circular Tumbler Screen |

| Transport Package | Export Wooden Packing |

| Specification | Stainless steel/carbon steel |

| Trademark | Sanyuantang |

| Origin | China |

| HS Code | 8474100000 |

| Production Capacity | 5000per/Year |

Product Description

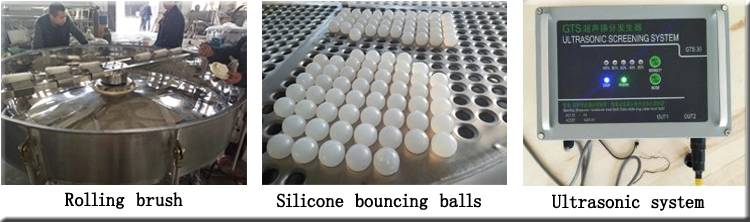

Circular tumbler screen of overviewTumbler screen machine is designed to meet the large output and high precision screening requirements,and it is a special design of an efficient screening machine. It is a kind of low frequency rotary sieve machine,which rotary motion is similar to hand screening as a binocular fixation and both hands screening. It meets allthe fine & ultra-fine particulate materials and any shape material (ball, cylinder, piece and even irregular shape),especially for hard to process materials.

Our newest range of Tumbler Screen is one of the most efficient separators that can process fine mesh and reduces the screening time. It increases your capacity, efficiency, and it is an ideal choice for screening materials with low bulk density and fine particle requirements.It provides a 3-dimensional elliptical motion which allows the machine to set radial and tangential inclination. While the radial inclination allows the screening material to travel from the centre to outwards, the tangential inclination makes the screening material move in a circular motion.This intuitive motion of the machine allows the fine particles to pass through the centre of the screens and pushes coarse particles to the periphery, which can be discharged as per your requirements.

Applicable IndustryApplication industry

Circular tumbler screen is suitable for food industry, pharmaceutical industry, chemical industry and other spherical,cylindrical, flake, or even irregularly shaped materials that are easy to block the net and require precise screening.Application materials: citric acid, milk powder, starch, sugar, vitamins, spices, tea, feed, plastics, rubber, fertilizer,sugar and salt industry, renewable resources, EPS, PVI, PVC, resin, etc.

Products Model

| Model | Diameter(mm) | Sieving area | Space requirement | Maximum screen layer | Power(kw) |

| YBS-1000 | 1040 | 0.71 | 1.2 | 1-5 | 1.5 |

| YBS-1200 | 1250 | 1.11 | 1.6 | 2.2 | |

| YBS-1600 | 1580 | 1.83 | 2.5 | 2.2/4 | |

| YBS-2000 | 1880 | 2.62 | 4 | 2.2/4 | |

| YBS-2200 | 2100 | 3.46 | 4.84 | 3/4 | |

| YBS-2600 | 2650 | 5.31 | 7 | 5.5 |

Xinxiang Sanyuantang Machine Co., Ltd. is located in Xinxiang High-tech Industrial Zone. It is a large-scale vibration equipment enterprise integrating scientific research, production and sales. In 2016, it passed the ISO9001 international quality management system certification. The company is committed to the production and sales of vibrating screen equipment, conveying and lifting equipment. Our products mainly include gyratory sieve , circular tumbler screen, rotary vibrating screen, ultrasonic vibrating screen, linear vibrating screen, filter sieve, air flow sieve, ,lab test sieve shaker, and a series of products such as conveying and lifting equipment.

Our Services

All produts purchased in our company are guaranteed to keep in good repair for one year. If quality problems happen in guarantee period, our company will maintain for free.

a, Before sending the machine, we will test and adjust, so you can use directly when you get it.b, Operation video & instruction will be sent to clients, to help them use the machines better.

Additionally, our company provides technical support and fittings for life. After-sales service isn't restricted by time and we will solve your problems in time. If you are caught in some problems when using our products, welcome to contact us at any time.

a, Any problems occur while using, professional advice will be offered.

b, All kinds of frequently used parts are supplied all the year round.

FAQ

Q: What are you mainly specilized in?

A: Our company is a professional manufacture of vibrating screen sifter equipments(like rotary vibrating screen,ultrasonic sieving machine,linear vibrating screen,test sieve machine,trumbler screem,drum screen,direct discharge screen,airflow sieving machine,450 filter machine and so on);conveying equipment (like screw conveyor,bucket elevator,vertical vibration elevator and so on);honey machine(honey processing machine,honey filling machine)Q:What's your after-sales services?

A: 24 hours service online,you can tell your trouble any time

Q:What is the MOQ of our products?

A:Usually 1 set

Q:What is the payment terms?A. Usually use T/T,but Western Union is also available

Q:What's your delivery time?

A:Ususlly 7-10 working days,if the order is large,the time should be longer

Q:What's the advantage compared to other suppliers?

A:We are a factory,We have business directly with our customers,there isn't any link between customers,so we can offer competitive price for you.

| The proper selection of vibrating screen depends on the material, mesh size, output required, method of input etc: | |||

| 1. Name of material: _____ | |||

| 2. Moisture:_____% | |||

| 3. Specific gravity:_____ | |||

| 4. Capacity:________kg/ hour | |||

| 5. Screen layer:_______ | |||

| 6. Screen mesh size:______ mesh . ______ mesh. ______ mesh | |||

| 7. Voltage:______V, Frequency:______HZ, ______phase | |||

| 8. All 304 stainless steel or contact materials part is 304 stainless steel or all carbon steel? |

If you want to know more about vibrating screen machine,please contact me.

Prev: Automatic Dreg Discharging Horizontal Pressure Leaf Plate Type Filter

Next: Hot Sale Cassava Powder Sieving Machine Circular Automatic Tumbler Vibrating Screen

Our Contact